VERTICAL HARVEST GROWS UP: Innovative Jackson Hole greenhouse supplies community with fresh produce

It’s a Monday in late January and Chef Saul Sanchez sorts through his delivery from Vertical Harvest, a greenhouse located a few blocks away from the Persephone Bakery Poulangerie & Café in downtown Jackson Hole, Wyoming. There are three hues of cherry tomatoes, bunches of basil, flats of microgreens and a mix of petite lettuces.

Persephone offers a few salads created from Vertical Harvest produce. In the roasted squash and burrata salad, sunflower micros and mixed greens are piled atop half-moons of roasted acorn squash that nestle a generous hunk of burrata. The Vertical Harvest Panzanella salad features the greenhouse’s cherry tomatoes—tossed with shaved fennel, pine nuts, basil, currants, crispy prosciutto bits and warm levain croutons on a bed of greens so tender and fresh you’d swear they were just plucked from the ground.

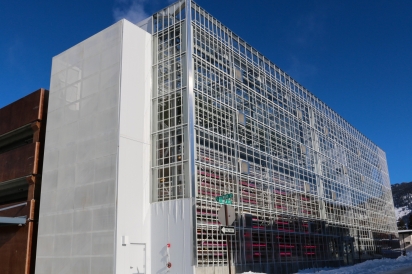

The greens were indeed just-picked, but not from the ground. Vertical Harvest is a hydroponic greenhouse built on what was formerly a vacant lot next to a parking garage. The three-story greenhouse sits on a sliver of land, just one tenth of an acre, but yields as much produce as a five-acre conventional farm. By installing growing carousels that rotate up to the ceiling, the urban farm’s innovative design turns the 4,500-square-foot footprint into 18,000 square feet of growing area.

“It’s like three farms stacked on top of one another,” said Vertical Harvest co-founder and CEO Nona Yehia. In 2009, Yehia, an architect in Jackson Hole, teamed up with co-founder Penny Mcbride, a local greenhouse enthusiast and leed accredited Professional. Together they envisioned a hydroponic greenhouse that would feed the community with nutritious, fresh produce year-round.

In Jackson Hole, winters are long and the growing season is short. With just 30 frost-free days each year, farmers work hard to crank out produce in the summer and fall. Some extend the season by a few months with greenhouses and hoop houses, but there’s not a lot of farming going on in the winter.

Currently, only 5% of the food consumed in Jackson hole is locally produced. As Vertical Harvest wraps up its first year of operations, the greenhouse is approaching its goal of producing 100,000 pounds of produce, including 40,000 pounds of tomatoes. Yet Yehia admits this will likely meet only 1% of the county’s need.

“We are just the tip of the iceberg in terms of addressing the demand for local food in our community,” she said.

Ian McGregor, board president of slow food in the Tetons, likens Vertical Harvest to the first airplane. “It’s one of the first of its kind,” he said. “It excites and motivates people to build structures like them so we are not so dependent on global systems to ship in food.”

Vertical Harvest supplies produce to area grocery stores, restaurants, the salad bar of the Jackson hole high school, and the diabetes education Program at st. John’s Medical Center.

But no one is more enthusiastic about working with Vertical Harvest produce than Jackson Hole chefs. Before the greenhouse was even built, Yehia and Mcbride created the Culinary Circle, a core group of local restaurants and grocery stores who agreed to purchase 95% of the greenhouse’s produce. Partnering with chefs to secure a revenue stream was a key facet of their early business plan.

Jarrett Schwartz, a private chef and restaurant consultant in Jackson, has created many dishes using Vertical Harvest produce. He especially

loves pairing foods with Vertical Harvest’s 18 varieties of microgreens. “There’s so much flavor packed inside each little green,” he said. “I love micro shiso with truffled tuna, the licorice-flavored micro chervil with tataki and the red bull’s blood beet micros with anything earthy, like steak.”

Yehia and Mcbride built Vertical Harvest with another key mission in mind: to employ people with intellectual and physical disabilities. Yehia grew up with a developmentally disabled brother and was acutely aware of the need for meaningful jobs for disabled adults. The staff of Vertical Harvest includes 15 people with conditions such as down syndrome, autism, seizure disorders and spina bifida. Whether they are staffing the front desk or delivering produce to area restaurants, these Vertical Harvest workers are not just employed—they are integrated into the workplace and the community.

On the third floor of the greenhouse where the tomatoes grow, it’s hot and steamy despite the subzero temperatures outside. Cherry “bumblebee” tomato plants, named for the hive of bees that reside in the tomato wing, reach up to the sky framed by snowy buttes on either side. Sean Stone, one of Vertical Harvest’s employees with intellectual disabilities, tells me he loves picking tomatoes but it’s easy to get dehydrated because of the heat. He said his favorite part of working at Vertical Harvest is making deliveries around town. “I know it’s an important job to be the person who delivers the food.”